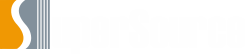

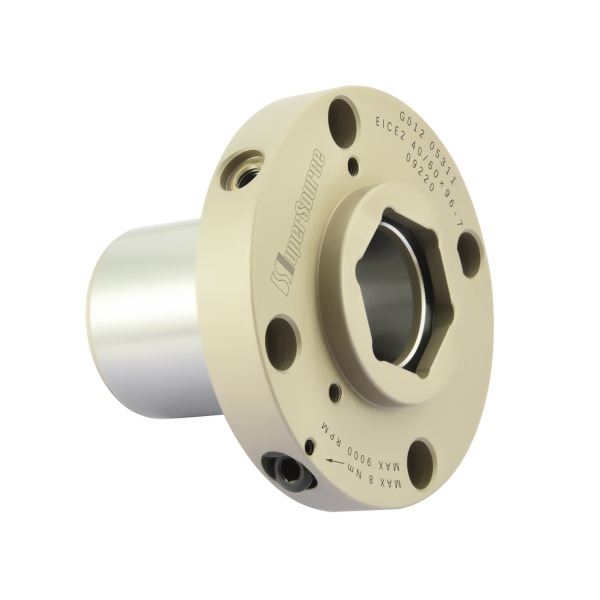

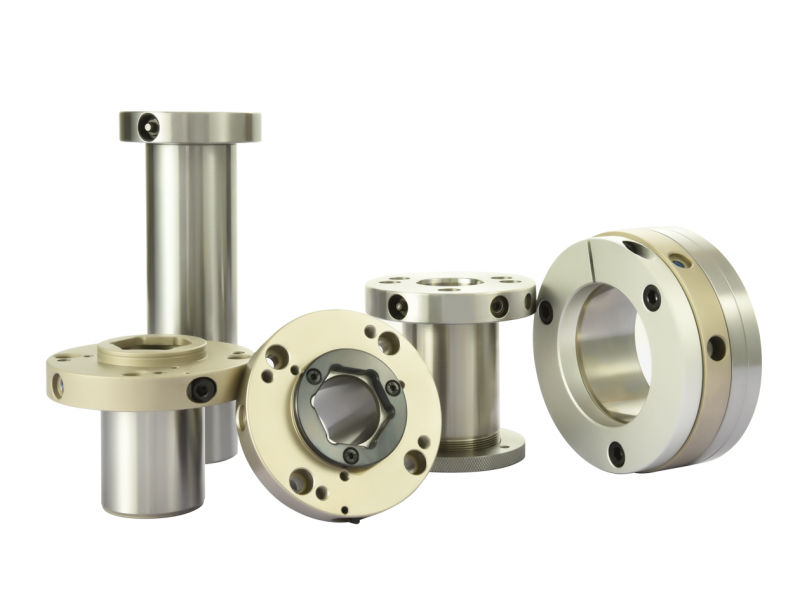

Hydro-lock Sleeves

SuperSource Hydro-lock Sleeves represent a versatile and cost-effective product line designed to meet the demands of woodworking applications that require rapid tool changes, secure clamping, and high-precision self-centering. Utilizing either pressure screw or grease pump pressurization systems, these sleeves transmit expansion force through a liquid medium to achieve automatic centering and locking between the spindle and tool hub. With both interchangeable and permanent assembly options—supporting inward, outward, or dual-direction expansion—our lineup accommodates a wide range of tooling configurations and machine types. Our advanced models such as SB3, SC3, AIL, and SQS2 exemplify our commitment to precision engineering, delivering industry-leading concentricity and radial runout. Offered in various sizes with flexible bolt connection settings, SuperSource Hydro-lock Sleeves integrate seamlessly with most machines on the market. In addition to our standard offerings, we provide custom-engineered solutions tailored to specific performance requirements, ensuring optimal reliability and productivity for professional woodworking operations.

Pressurizing Systems

Pressure Screw Pressurizing systemPressure setting and tools assembly are achieved by fastening the Allen screw on the hydro-lock sleeve using T-wrench. Loosening the screws to enable quick disassembly and replacement of the tools.

Grease Pump Pressurizing SystemUse a high-pressure grease pump to set the pressure according to product specifications.

Assembly Mode

Interchangeable AssemblySleeve expands both inward and outward (i.e., the inner ring expands to clamp with the spindle and the outer ring expands to connect with the tools) to achieve automatic centering between spindle and tools. This assembly mode enables quick and easy change of tools.

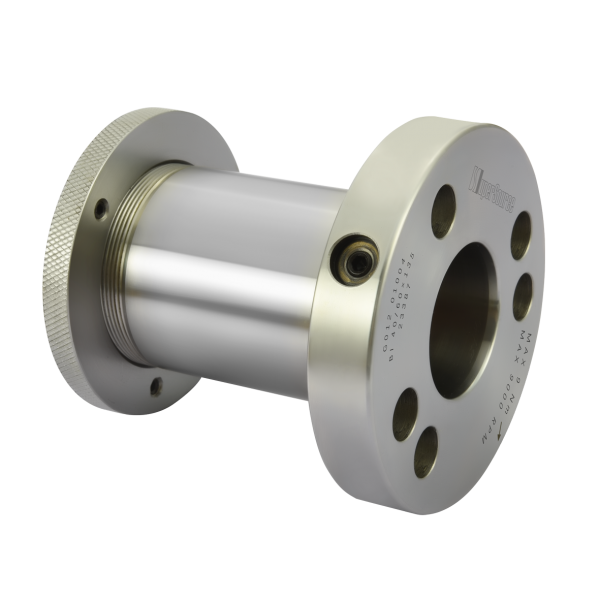

Permanent Assembly (Inward Expansion)Sleeve only expands inward to clamp with the spindle, while the sleeve and tools are connected through bolts. This assembly mechanism is structurally simple and the sleeves using this mode are typically smaller in size.

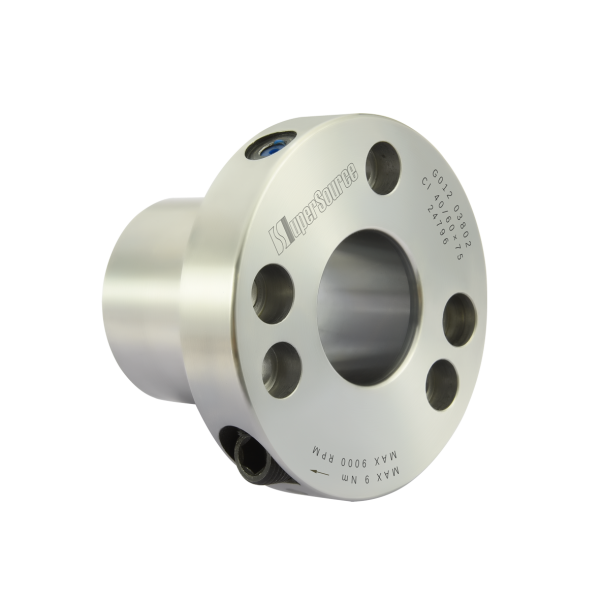

Permanent Assembly (Outward Expansion)Sleeve only expands outward to be fastened with tools, while the sleeve and spindle are connected through bolts. This assembly mode is adopted for hydraulic expansion shafts and tool holders.