Cutterheads

SuperSource cutterheads are engineered for precision, reliability, and ease of use—made possible through high-quality materials, advanced CNC machining, and rigorous inspection processes both online and offline. When paired with our interchangeable and regrindable corrugated knives which are designed to exceed the most demanding EU OEM standards—these cutterheads are ideal for a wide range of wood profiling and surface finishing applications.

Our cutterhead lineup includes straight bore, hydraulic locking, HSK interface and spiral insert models, compatible with corrugated, planer and insert knives alike. In addition to the standard options featured in our catalog, we also offer fully customizable solutions. Clients can specify bore size, cutting angles, knife pocket geometry, pocket depth, and more to meet their unique processing requirements.

Downloads:

SuperSource Cutterhead Catalogue PDFCutterhead Series

Straight Bore Cutterheads

This is the most widely used type of cutterhead in the market, designed for clearance-fit assembly with moulders. Known for their simple structure, straight bore cutterheads place minimal demands on the machine system, making them a reliable and cost-effective choice for general-purpose applications.

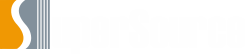

Hydraulic Locking Cutterheads

Designed for high-speed machines with precise tolerances, hydraulic locking cutterheads deliver superior performance where accuracy and stability are critical. Unlike straight bore cutterheads, these models use a pressurized sleeve to ensure an exceptionally tight fit on both the grinder and the moulder, enhancing cutting precision and consistency. Our hydraulic locking cutterheads are manufactured from high-strength steel or aluminum alloys, CNC machined to exact tolerances, and dynamically balanced to ISO G2.5 standards for speeds up to 8,000 RPM. These features ensure excellent surface finishes, extended tool life, and reliable performance in continuous high-speed operations. We offer two variations: 1) Hydro-lock cutterhead, which is pressurized with a grease pump; and 2) Easy-lock cutterhead, which is pressurized with built-in screws.

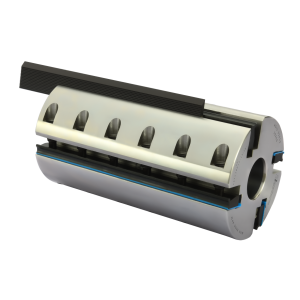

SuperHelic Cutterheads

The SuperHelic™ series—comprising both SuperHelic™ cutterheads and their matching corrugated knives—is a patented solution developed exclusively by SuperSource. This system features a continuous compound shear cutting action that slices through wood with minimal tool pressure and reduced vibration. The result is exceptionally smooth cutting performance, even on challenging materials such as cross-grain or knotted wood. By minimizing common surface defects like fuzziness and tear-out, the SuperHelic™ system significantly reduces or eliminates the need for additional sanding. Cutterheads in this series are available in both straight bore and hydraulic locking configurations, with outer diameters of 125 mm or 160 mm to suit various machine setups and applications.

Powerlock Cutterheads

SuperSource Powerlock cutterhead is engineered for high-speed, high-precision woodworking applications, offering rapid tool changes and exceptional machining accuracy. Utilizing the HSK-85WS Powerlock interface, these cutterheads integrate seamlessly with compatible moulders to minimize setup time and maximize productivity. Constructed from high-strength steel alloy, SuperSource Powerlock cutterheads are CNC-machined to exacting tolerances and dynamically balanced to ISO G2.5 standards, supporting operating speeds up to 12,000 RPM. This precision engineering ensures smooth operation, reduced vibration, and superior surface finishes, even during continuous high-speed production.