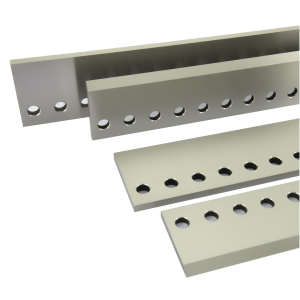

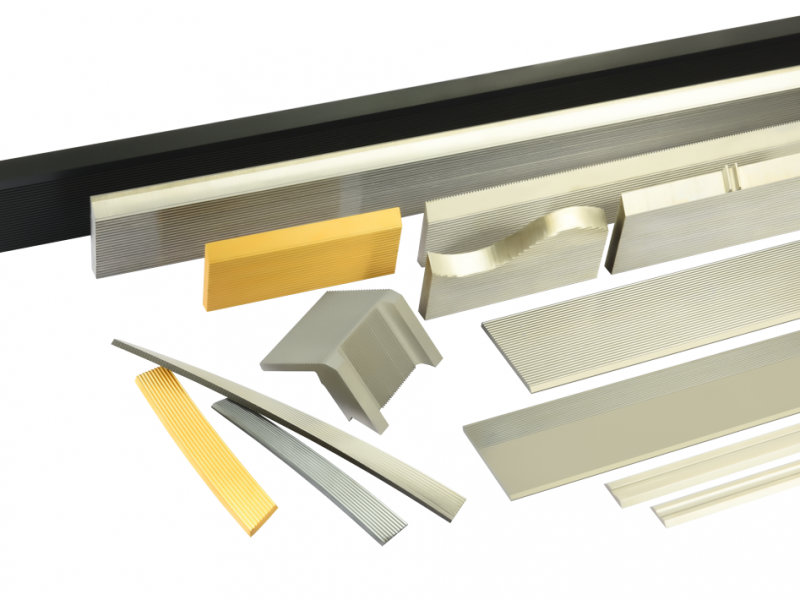

Knives

SuperSource Tooling has been a trusted name in the woodworking industry for decades, renowned for producing reliable and versatile cutting tools. Our commitment to excellence is evident through our advanced processing technologies, specialized manufacturing equipment, and stringent quality control measures, ensuring that each product meets the highest standards of performance and durability. Our comprehensive range of woodworking knives includes planer knives, quick-lock planer knives, corrugated knives, SuperHelic™ knives, Williams & Hussey (W&H) knives, and custom-designed knives to meet specific requirements. These knives are crafted from premium materials such as D2 high-carbon high-chromium steel, various high-speed steels (including V2, M2, T1, and M3+), tungsten carbide-tipped (TCT) inlaid, and solid carbide. To further enhance performance and longevity, we offer specialized coatings like WR, BNv, and ER+, which improve wear resistance and reduce friction.

Each knife undergoes rigorous quality control processes, including precise CNC machining and advanced heat treatment, to ensure exceptional cutting performance and durability. Our products are designed to deliver finer cutting finishes and longer service life, making them a preferred choice for professionals worldwide. With a presence in over 37 countries and regions, SuperSource Tooling continues to provide innovative and reliable solutions for the global wood processing industry.

Downloads:

SuperSource Knives Catalogue PDFKnife Materials

SuperSource Tooling is deeply committed to the research and development of advanced materials and innovative coating technologies. In addition to our proven offerings, we are actively testing new-generation steels and coatings now entering mass production. We welcome inquiries from customers seeking performance-driven tooling solutions. Our mission is to deliver not only superior durability and cost-effectiveness, but also a healthier working environment—by reducing tool wear, minimizing noise, and lowering airborne dust in woodworking operations.

High Carbon and High Chrome (HCHC) Steel

AISI/ASTM D2 is a widely used base material for knives in moulding and planer applications. With 12% chromium and a Rockwell hardness of 58 HRC, it offers excellent resistance to chemical erosion, especially when cutting wet cedar or redwood. Easy to grind and resistant to nicking in knotty softwoods, D2-HCHC is ideal for softwoods and short production runs in hardwoods.

High Speed Steel (HSS)

V2 grade high-speed steel is a special steel blend with extra Vanadium designed for woodworking tools. With an increased level of Vanadium to replace more expensive Molybdenum, V2-HSS provides excellent tool life and a lower price than any other HSS in the market. At a moderate feeding speed, V2-HSS offers similar wear life and performance as M2-HSS. V2-HSS has a 63 HRC and is great for most long runs in soft or hardwoods.

AISI/ASTM M2 grade high-speed steel offers 25% longer run times than D2 grade. Our premium M2-HSS offers high levels of Tungsten (6% W), Molybdenum (5.5% Mo), and Vanadium (2.2%V). M2-HSS is hardened to 63 HRC for better wear resistance in harder woods. Great for long runs in most soft and hardwoods.

AISI/ASTM T1 grade high-speed steel offers 25% longer run times than M2 grade. Our T1-HSS contains 18% tungsten and delivers superior red hardness and wear resistance. With 62–66 HRC hardness, T1-HSS is optimized for high-speed cutting and excels in applications involving abrasive glue lines. T1-HSS is preferred by mills that primarily run hardwoods or softwood mills that want the ultimate cutting performance.

AISI/ASTM M3+ high-speed Steel (AISI) offers up to 100% longer tool life over M2-HSS. This superalloy steel is excellent for long runs or on tough hardwoods. M3+ HSS contains high levels of Vanadium, Tungsten, Molybdenum, and Chromium for extended wear life. Treated to 66 HRC, which is one of the hardest HSS offered.

High Speed Steel with Coatings

BNv grade uses SuperSource's premium high-speed steel as base material, enhanced with a case-hardened carbon nitride layer and black oxide coating to reduce pitch build-up. This material offers up to 100% longer tool life compared to standard HSS, without compromising on ease of profiling. Featuring a wear-resistant 0.01" cutting edge with a hardness exceeding 72 HRC, BNv grade performs exceptionally well in long production runs and when working with dense or stubborn hardwoods.

Our WR grade offers exceptional value and durability for everyday woodworking applications. With a cutting edge hardened to 72 HRC and a long-wearing diamond dust chrome coating applied to the face, this material provides up to 100% increased tool life at a modest additional cost. WR grade is particularly effective for most hardwoods and can triple tool life in wet woods that contain tannic acids (oak, cedar, redwood).

Our "Endurance" super run (ER+ Grade) steel is engineered for the most demanding production environments. It delivers up to 800% longer tool life than standard HSS by using a proprietary PVD coating process. The coating, applied via magnetron anion sputtering, forms a multi-layer film of titanium, ceramic crystals, and other compounds, achieving a surface hardness of over 3500 HV—twice as hard as C2-grade carbide. Despite its extreme hardness, the coating is thin enough to allow re-profiling with conventional vitrified or CBN grinding wheels. It is ideal for short-run production in difficult materials like MDF, teak, Ipe, and Angire.

Carbides

TCT inlaid knives combine affordability with performance by welding a cemented tungsten carbide blade onto a steel body using advanced bonding technology. These knives are widely used in the processing of MDF, particleboard, plywood, hardwood, and solid wood. They deliver cutting performance comparable to solid carbide tools while offering cost advantages, making them an efficient choice for medium-duty operations across various wood-based materials.

C3-grade carbide is among the hardest materials used in woodworking, achieving a Rockwell hardness up to 93 HRC. It offers outstanding wear resistance, red hardness, mechanical strength, and corrosion resistance. These properties make C3 carbide knives particularly suitable for processing abrasive materials such as high-impurity hardwoods, mineral-laden woods, and synthetic or glued wood composites. Their superior durability makes them ideal for applications where tool longevity and cutting precision are critical.